Ideal Insulation with Cold Room Door Seals and Base Profiles

Table of Contents

- How Do Cold Room Door Seals Affect Energy Efficiency?

- Is It Possible to Improve Insulation Performance with Base Profiles?

- Which Seal and Profile Type is Better for Cold Room Doors?

- Notable Innovations in Cold Room Door Insulation in 2025

- Maximum Insulation with Next-Generation Door Seals and Base Profiles

- Sustainable and Functional Cold Room Door Solutions

How Do Cold Room Door Seals Affect Energy Efficiency?

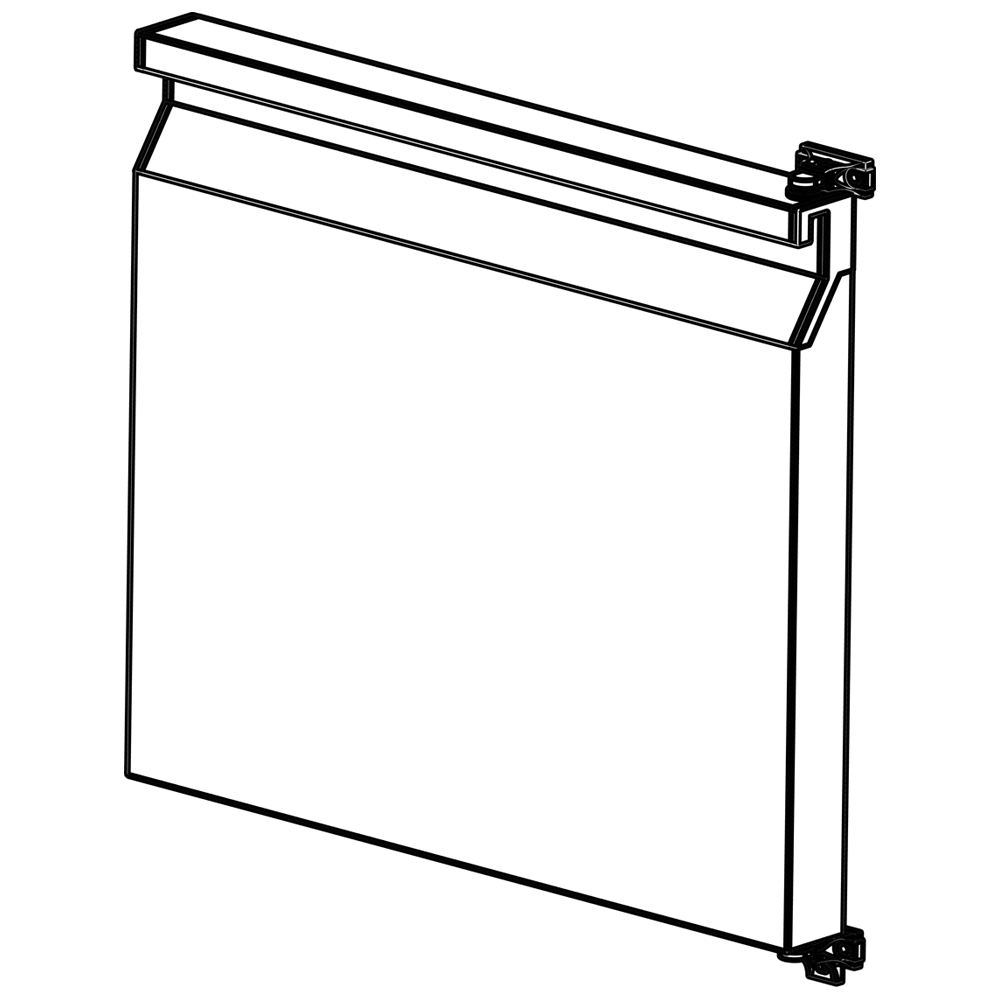

In cold rooms, energy efficiency is directly related to the correct use of door seals. İmamoğlu highlights that the insulation of cold room doors plays a critical role in preventing energy loss. Door seals keep the cold air inside, reducing energy consumption and lowering electricity costs.

Insufficient or old door seals significantly impact the performance of the cold room. Air leaks cause the cooling system to run continuously, which both increases energy costs and shortens equipment lifespan. İmamoğlu emphasizes the importance of regular inspections and using proper seals.

To increase energy efficiency, high-quality seals should be preferred. Materials like silicone or EPDM stand out for durability and flexibility. These materials ensure perfect door closure, preventing warm air from entering and minimizing energy loss. Additionally, proper installation of seals directly affects performance.

Another key factor in energy efficiency in cold rooms is regular maintenance. Wear or deformation of door seals reduces insulation effectiveness. İmamoğlu notes that consistent maintenance is critical for long-term energy savings and operational efficiency.

Using appropriate base profiles and door accessories is also crucial to optimize energy efficiency. These components strengthen door sealing and maximize cold room performance. The right combination of products and maintenance reduces energy costs while improving operational efficiency.

Is It Possible to Improve Insulation Performance with Base Profiles?

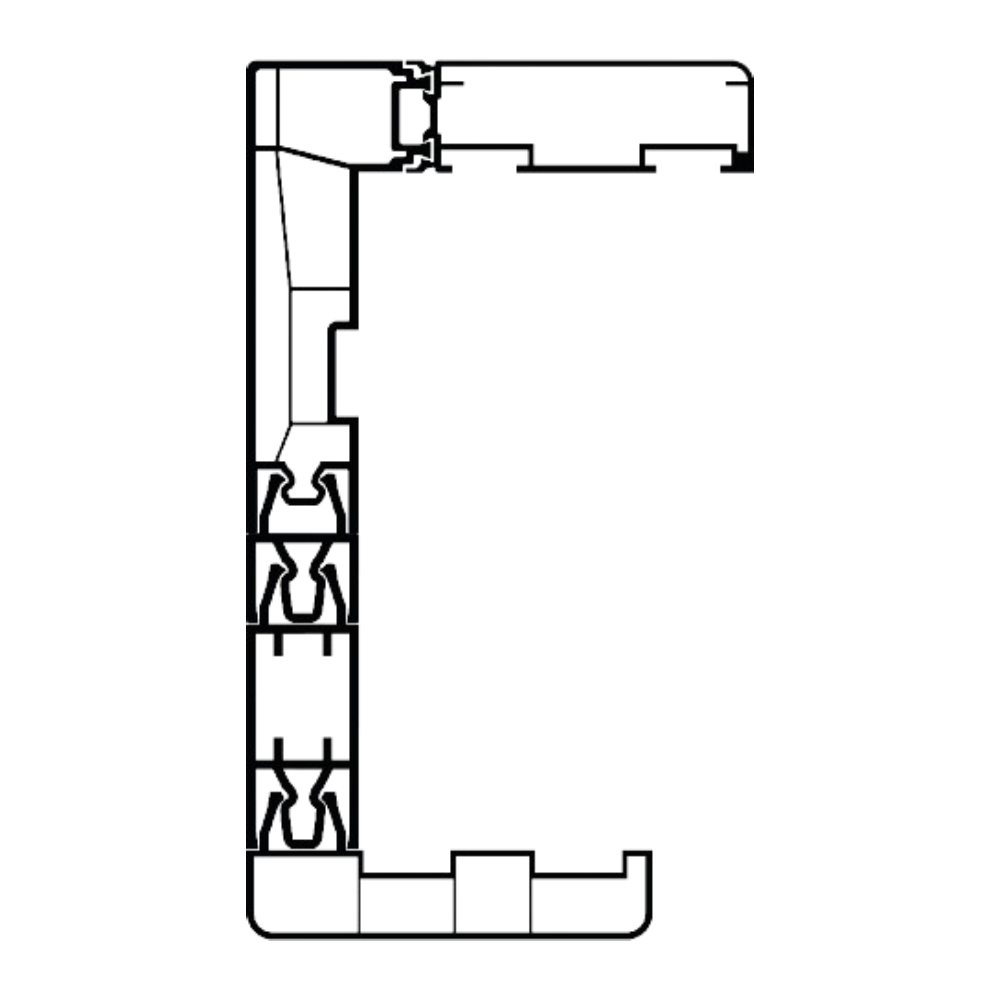

In industrial and commercial spaces, base profiles play a critical role in enhancing insulation performance. İmamoğlu emphasizes that proper base profiles minimize gaps under the door, preventing cold or hot air leaks. This is crucial for energy savings and reducing operational costs.

One of the most important factors affecting insulation performance is the profile material and its flexibility. EPDM or silicone base profiles provide consistent tight contact at the bottom of the door thanks to their durable and long-lasting structure. İmamoğlu explains that these materials improve thermal insulation and reduce energy loss, enhancing efficiency.

Installation quality is also a decisive factor in insulation performance. Incorrect or incomplete installation reduces the desired insulation level and causes leaks. İmamoğlu highlights the importance of professional installation and periodic inspections. Regular maintenance and cleaning preserve the effectiveness of profiles.

Another way to enhance base profile performance is to use compatible accessories. When door seals and bottom profiles work together, sealing is maximized. İmamoğlu states that this combination reduces energy costs and optimizes insulation performance in facilities.

Correctly selected and installed base profiles not only save energy but also increase operational efficiency. İmamoğlu points out that the combination of high-quality materials and professional installation maximizes insulation performance.

Which Seal and Profile Type is Better for Cold Room Doors?

In cold room doors, seal types and profiles are extremely important for energy efficiency and insulation performance. İmamoğlu emphasizes that selecting the right door seals and bottom profiles plays a critical role in maintaining the cold chain. Wrong choices can cause unwanted warm air leaks and increase energy costs.

The most preferred seal materials include EPDM and silicone. EPDM seals provide tight sealing during door closure due to their durable and flexible structure. Silicone seals maintain flexibility even at low temperatures, enhancing cold room performance. İmamoğlu notes that both materials have high insulation capacity.

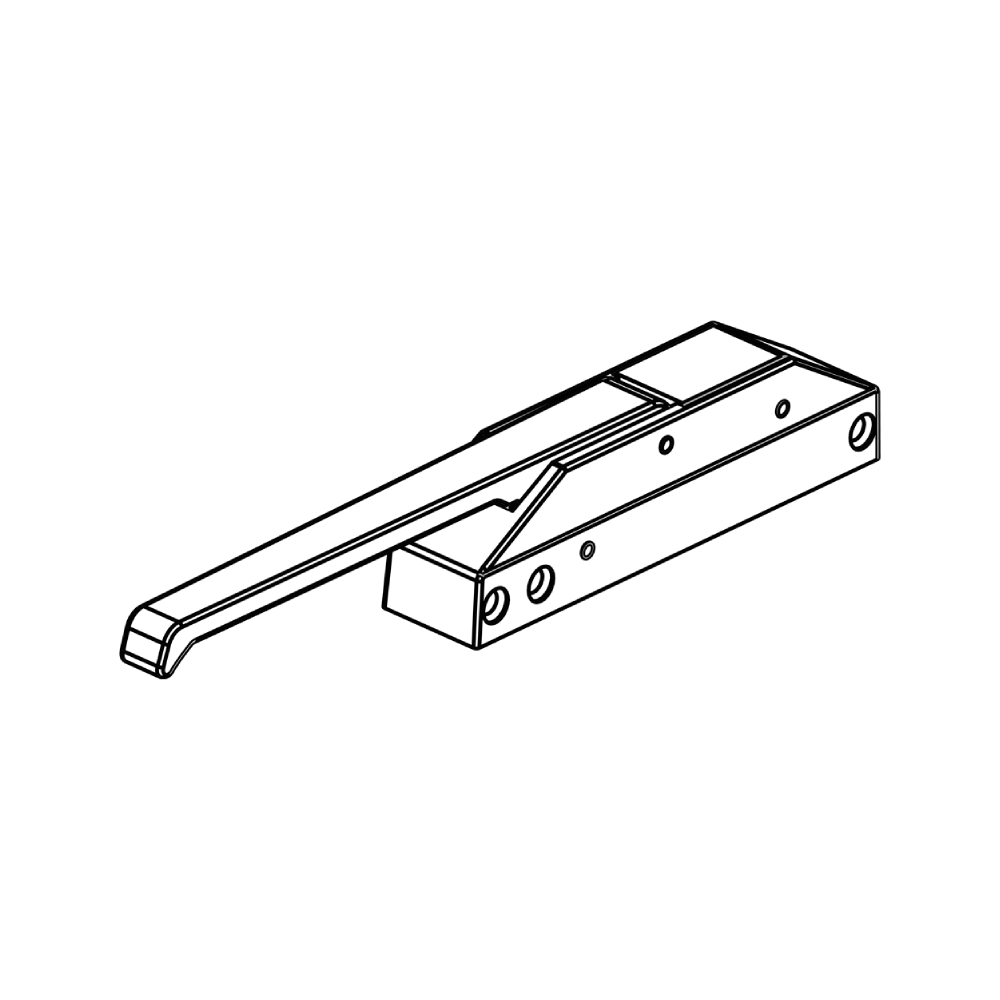

The type of bottom profiles also affects insulation quality. Double-layered and magnetic profiles minimize air passage during door closure and prevent energy loss. İmamoğlu explains that these profiles, when compatible with door seals, increase efficiency. Durable and flexible profiles are especially important in high-traffic areas.

Proper installation is critical for seal and profile compatibility. Incorrect or incomplete installation reduces seal performance and negatively affects insulation. İmamoğlu emphasizes that periodic inspections and maintenance are necessary for long-term performance.

Correct cold room door seal and profile selection not only saves energy but also ensures a safe and efficient working environment in facilities. İmamoğlu states that the combination of high-quality materials and professional installation is decisive in this process.

![]()

Notable Innovations in Cold Room Door Insulation in 2025

The year 2025 brings significant innovations in the field of cold room door insulation. İmamoğlu highlights new seal and profile technologies developed to increase energy efficiency and protect the cold chain. These innovations improve operational performance in both industrial facilities and retail cold storage.

Next-generation door seals are made from materials that maintain flexibility at low temperatures. EPDM and silicone-based seals maximize tightness during closure and minimize energy loss. İmamoğlu notes that these seals are long-lasting and reduce maintenance needs.

Innovations in bottom profiles are also notable. Magnetic and double-layered profiles block air passage between the door and the floor, providing energy savings. İmamoğlu explains that the compatibility of these profiles with seals is critical for improving cold room performance.

Installation and maintenance processes are optimized with 2025 innovations. Professional installation kits and measurement technologies ensure consistent insulation performance. İmamoğlu highlights that regular inspections and prompt interventions provide long-term energy savings and cost efficiency.

These new technologies not only enhance energy efficiency but also improve operational safety. İmamoğlu notes that these developments are critically important for industrial facilities.

Maximum Insulation with Next-Generation Door Seals and Base Profiles

In industrial facilities and retail cold storage, door seals and base profiles are key determinants of insulation performance. İmamoğlu’s next-generation seals provide tight sealing even at low temperatures due to their flexible and durable materials, minimizing energy loss and preserving product storage conditions.

New base profiles effectively close gaps between the door and the floor, preventing air passage. Magnetic and double-layered designs ensure complete sealing with every closure, enhancing insulation performance. İmamoğlu highlights that these profiles stand out for easy installation and long-lasting durability.

Control and maintenance processes are critical for maintaining continuous insulation. Regular measurements and professional installation kits ensure that door seals and base profiles maintain high performance. İmamoğlu states that these methods are effective in increasing energy efficiency and operational safety.

Next-generation solutions not only strengthen cold room insulation but also reduce overall energy costs in facilities. İmamoğlu’s technologies play a critical role in achieving maximum insulation and long-lasting use in modern industrial facilities.

Sustainable and Functional Cold Room Door Solutions

Choosing door solutions in industrial and commercial cold rooms is critical not only for energy efficiency but also for sustainability and usability. İmamoğlu’s modern cold room door systems are designed with eco-friendly materials and manufactured for long-lasting use, providing energy savings while reducing waste and maintenance costs.

Functional door seals and base profiles ensure tight sealing even at low temperatures, optimizing insulation performance. İmamoğlu emphasizes that specialized seals provide durability for long-term use. These features minimize energy loss while preserving product quality in cold rooms.

Functionality is also prioritized in installation and maintenance processes. Easily installable cold room door solutions maintain high performance with regular maintenance. İmamoğlu states that these solutions not only enhance energy efficiency but also support operational safety.

Sustainable design provides long-term cost advantages in industrial facilities, while functional solutions ensure usability and overall performance. İmamoğlu’s modern cold room door solutions stand out as an important choice for eco-friendly and high-efficiency operations in future industrial facilities.