Storage Optimization with Cold Room Stacking Shelves and PVC Accessories

Table of Contents

- How to Achieve Storage Optimization with Cold Room Stack Racks?

- 7 Ways to Increase Efficiency in Cold Room Storage with PVC Accessories

- Cold Room Rack Systems Selection Guide: Durability and Hygiene Tips

- Stack Racks vs PVC Accessories: Which Solutions Are More Efficient?

- Common Mistakes in Cold Room Storage and the Right Solutions

- Cold Room Stack Racks and PVC Accessories Storage Trends in 2025

How to Achieve Storage Optimization with Cold Room Stack Racks?

In industrial storage processes, cold room stack racks play a critical role in both efficiency and hygiene. Properly designed rack systems ensure products are stored in an organized, safe, and long-lasting manner. The İmamoğlu brand offers durable and ergonomic stack racks in cold room solutions, providing maximum benefit to businesses.

To achieve storage optimization, the layout plan of the rack systems should be carefully designed. Racks should not obstruct cold air flow, allowing products to be preserved evenly throughout the space. This ensures both energy savings and product safety.

Secondly, the material used in cold room stack racks must be stainless and food-safe. Especially in industrial kitchens or food storage areas, selecting products that comply with hygiene standards is crucial for the sustainability of businesses. İmamoğlu’s products in this area stand out for their durability.

Flexibility is also a critical factor. The ability to easily assemble and adjust rack systems to different heights provides an advantage for storage optimization. This allows different product types to be organized easily within a single system.

Load-bearing capacity should not be overlooked. Cold room stack racks should be designed to carry heavy loads for extended periods. Otherwise, deformation or safety risks may occur. İmamoğlu enables businesses to obtain long-term solutions with high-durability rack systems.

Finally, ease of maintenance and cleaning is also part of storage optimization. Racks that are easy to clean help maintain hygiene standards and ensure products are stored more safely.

7 Ways to Increase Efficiency in Cold Room Storage with PVC Accessories

PVC accessories used in industrial storage areas stand out for both functionality and durability. Proper accessory selection is critical, especially in the food and pharmaceutical sectors, to ensure cold rooms operate efficiently. The İmamoğlu brand offers high-quality solutions in this area, providing significant advantages to businesses.

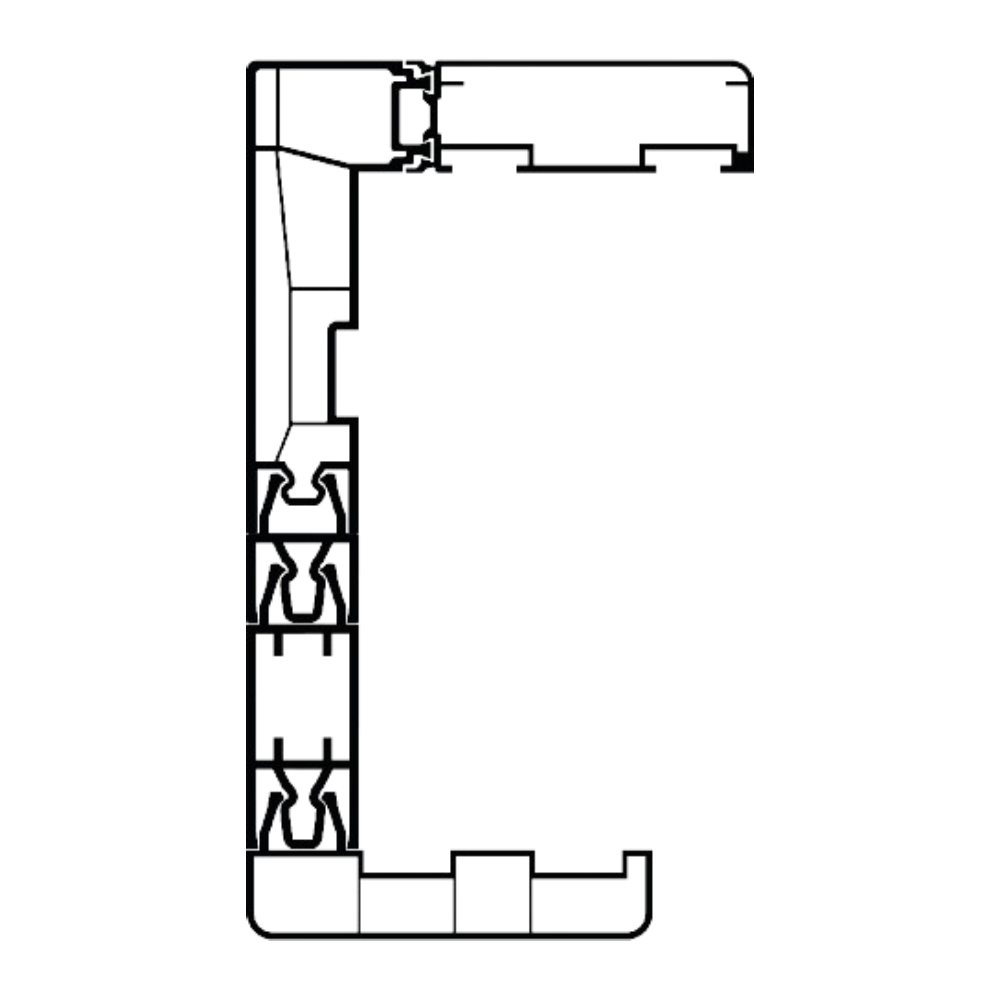

First, PVC accessories increase airtightness, preventing energy loss in cold rooms. Door profiles, seals, and strip curtains help retain cold air inside, reducing energy costs.

Second, PVC strip curtains used in cold room storage help maintain interior organization and protect products from external factors. This enhances food safety and hygiene standards.

A third way is to use modular PVC accessories to easily adapt rack systems and door solutions. This flexibility allows storage areas to be shaped according to needs.

Fourth, PVC profiles in cold room storage provide long-lasting use with their corrosion-resistant structure. In particular, PVC materials are an important alternative against deformation of metal components in humid environments.

The fifth way is to improve user ergonomics with PVC accessories used in door hinges and handles. Easily opening and closing doors increase speed and efficiency in operational processes.

Sixth, PVC surfaces in cold room storage make cleaning and maintenance easier, providing businesses with significant hygiene advantages. Practical cleanability means time and labor savings.

The seventh way is to achieve long-term cost benefits with durable PVC accessories offered by reliable brands like İmamoğlu. These accessories increase operational efficiency and reduce maintenance costs.

Cold Room Rack Systems Selection Guide: Durability and Hygiene Tips

Cold room rack systems used in the food, pharmaceutical, and logistics sectors directly affect the efficiency of storage processes. If the selection is not made correctly in terms of both durability and hygiene, product safety and business efficiency can be at risk. Therefore, there are important criteria to consider when choosing rack systems.

First, the durability of cold room rack systems should be prioritized. Stainless steel and galvanized materials can be used for long periods even in highly humid environments. In this regard, the high-quality solutions offered by the İmamoğlu brand are frequently preferred in the sector.

Hygiene is another critical point for cold room rack systems. Easy-to-clean surfaces prevent bacterial formation and protect food safety. This feature is indispensable for businesses storing dairy products, meat, and fish.

Storage capacity is another factor to consider when selecting rack systems. Modular cold room rack systems easily adapt to growing business needs and optimize space usage.

Corrosion resistance should also be considered during the selection process. Racks used in areas exposed to high humidity should not rust, protecting long-term investment. Durable cold room rack systems made from high-quality materials provide a significant advantage.

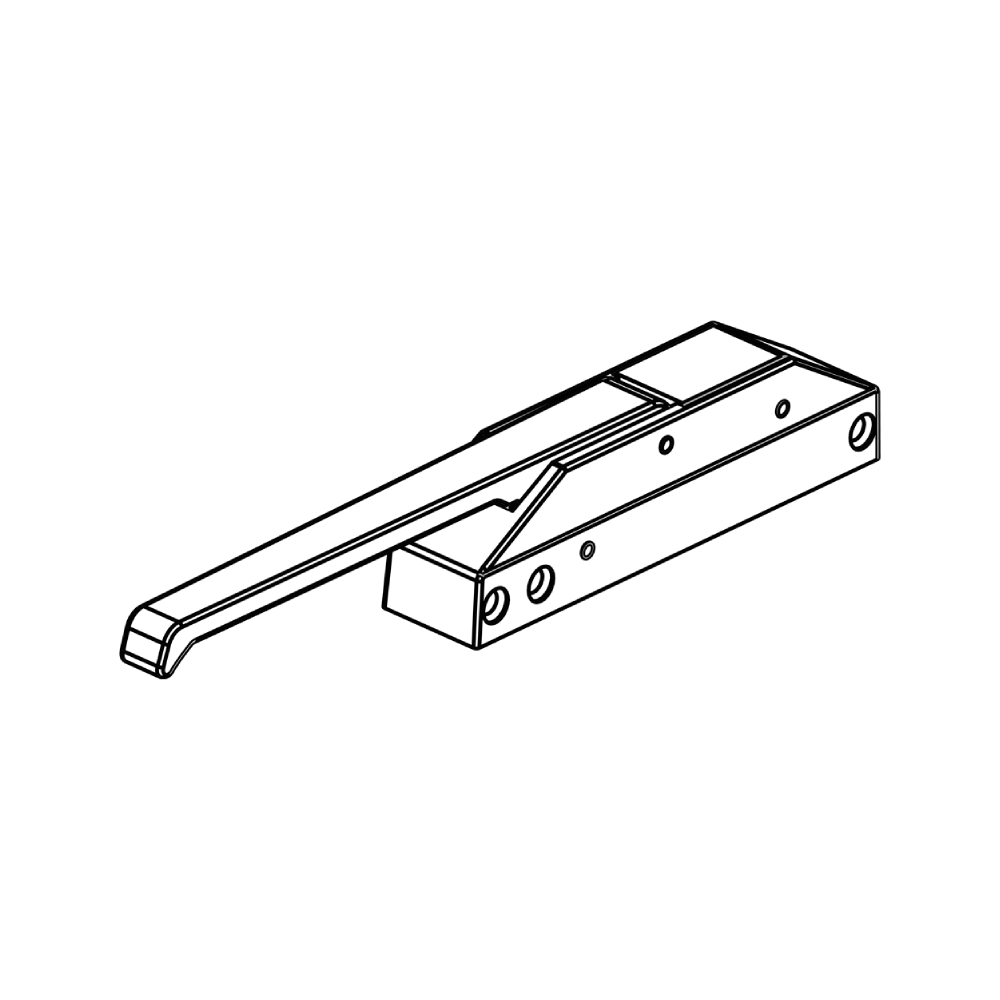

Ergonomics and ease of use should not be overlooked. Easily assembled and adjustable racks speed up work processes and make regular stock control easier for businesses.

Finally, cold room rack systems designed to meet your business’s specific needs increase storage capacity and save energy. İmamoğlu provides solutions that combine hygiene and durability, offering long-term benefits to businesses.

Stack Racks vs PVC Accessories: Which Solutions Are More Efficient?

Stack racks and PVC accessories used in storage processes are among the most critical components for organization and efficiency. Both solutions offer different advantages, but incorrect choices can lead to inefficient use of storage space and weakened hygiene standards. Therefore, a comparative evaluation provides important guidance for businesses.

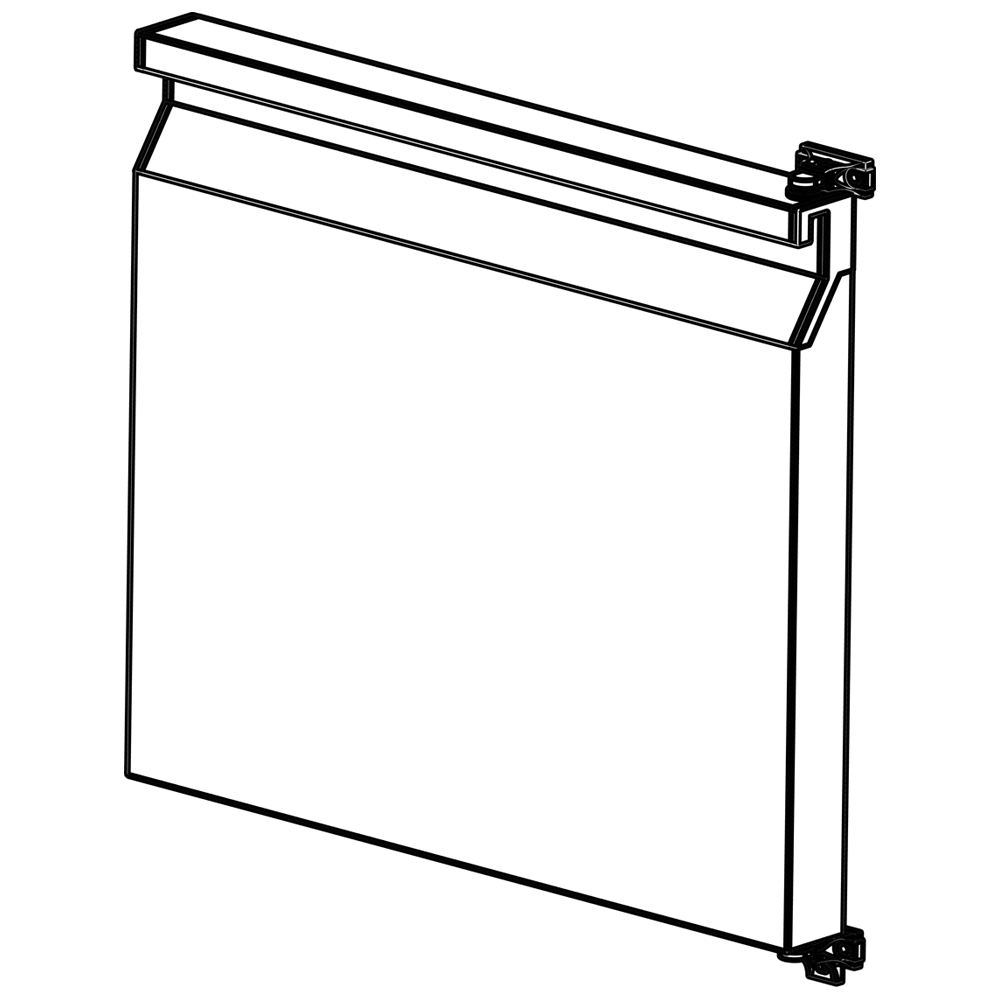

Stack racks are especially effective for organizing and safely storing large-volume products. Made from steel or aluminum, these systems provide long-lasting solutions in terms of durability. Their resistance to high weights makes them indispensable in the logistics and food sectors. Additionally, stack racks optimize space usage, achieving maximum efficiency even in small storage areas.

On the other hand, PVC accessories provide complementary solutions that ensure hygiene and practicality in storage areas. These accessories, especially used in cold rooms, stand out for their resistance to humidity and temperature fluctuations. PVC accessories are easy to clean, enhancing food safety and hygiene standards. They also offer easy installation, saving businesses time.

When compared, stack racks focus more on increasing storage capacity and durability, while PVC accessories stand out for hygiene, ergonomics, and ease of use. Combined use of these two solutions provides maximum efficiency for businesses. İmamoğlu’s rack systems and accessory solutions combine durability and hygiene, making them a reliable choice in the industry.

Common Mistakes in Cold Room Storage and the Right Solutions

Cold room storage is crucial for food safety and business efficiency. However, many businesses face product loss, energy waste, and hygiene issues due to mistakes made in this area. Being aware of these mistakes and applying the right solutions positively affects both quality and cost control.

One of the most common mistakes in cold room storage is obstructing airflow. Incorrect placement of racks or products prevents cold air from distributing evenly. As a result, some products spoil faster while others freeze unnecessarily. The correct solution is to leave appropriate gaps between racks for air circulation and pay attention to stack racks usage.

Another mistake is selecting inappropriate materials. Racks prone to rust or low-quality PVC accessories negatively affect both hygiene and durability. The solution here is to choose high-quality materials and use long-lasting products. İmamoğlu stands out in this regard, offering durable and hygienic solutions that provide businesses with reliability.

Additionally, failure to regularly monitor temperature is a major issue. When digital thermometers and monitoring systems are not used in cold room storage processes, even small temperature fluctuations can cause food spoilage. The correct solution is to perform regular maintenance and support temperature control with automation systems.

Finally, neglecting hygiene rules is among common mistakes. Insufficient cleaning leads to mold and bacterial growth. To prevent this, easy-to-clean rack systems and moisture-resistant PVC accessories should be used. This ensures a hygienic environment and extends product shelf life.

Cold Room Stack Racks and PVC Accessories Storage Trends in 2025

The use of cold rooms is becoming increasingly critical across many sectors, from the food industry to pharmaceuticals. By 2025, not only cooling capacity but also the durability, hygiene, and flexibility of storage systems are gaining importance. At this point, stack racks and PVC accessories stand out as solutions that make a difference in businesses’ storage strategies.

One of the most notable trends of the new era is modular stack racks. Businesses prefer these rack systems, which can be easily adjusted according to changing stock volumes. Especially, stainless steel frames that increase durability and easy-to-clean surfaces provide an advantage in terms of food safety. İmamoğlu offers innovative solutions in this area, enhancing both efficiency and long-term investment opportunities.

Another emerging trend in 2025 is the increased use of PVC accessories. Accessories such as corner protectors, non-slip bases, and airtight connection elements elevate both safety and hygiene. PVC accessories provide long-lasting use by reducing the risk of deformation in humid and low-temperature environments.

Digitalization is also shaping cold room trends. Smart sensors and automatic tracking systems continuously monitor critical factors such as temperature, humidity, and airflow in storage areas. Combined with correctly positioned stack racks and durable PVC accessories, these technologies enable businesses to achieve maximum efficiency in warehouse management.

As hygiene standards become increasingly strict, choosing stack racks with easy-to-clean surfaces and PVC accessories with antibacterial properties further strengthens food safety. The trends in this area in 2025 emphasize not only storage but also sustainability and energy efficiency.